|

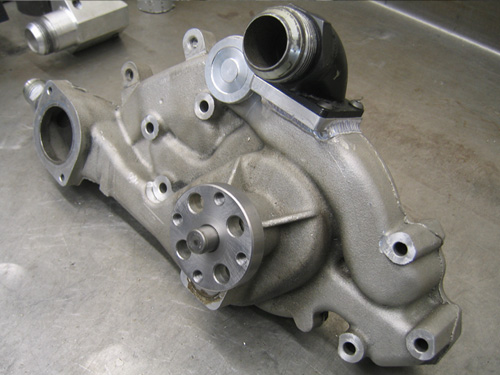

The second factor referred to earlier regarding waterpump impendence is the pulley/pump part of the equation. This brings several related issues. The pulley itself is inadequate in a couple of regards. In our case, one obvious issue is width. The stock foot print will not accept the 45mm wide belt we need to use. The second very important issues, but not as obvious, is the strength of the pulley. The stock pulley wall thickness is inadequate for the load we intend to transmit. This is often overlooked when dealing with belt drives serving modified applications. When the pulley strength is not sufficient a number of things or combinations of things can result. Under load spikes, caused from sharp throttle manipulation (such as shifting, etc.), pulley's can flex or oblong. This, in effect, decreases tension on the belt (especially if a static <fixed> tensioner is used) for that period the flex is being experienced, (often dynamic <spring loaded> tensioners can not respond quick enough and the same result is experienced). Depending what type of belt is used, serpentine or cogged, slightly different results will occur, although commonly the belt will be compromised and normally fails immediately. We've experienced some cases that the oblong deflection is so violent that it flicks the pulley off the shaft. Definitely an experience to be avoided. This issue is not unique to stock components, we have experienced with some aftermarket upgrades so beware. Our solution to this problem begins with the production and install of a bolt hub pressed onto the stock LS-2 waterpump. |

|

|