|

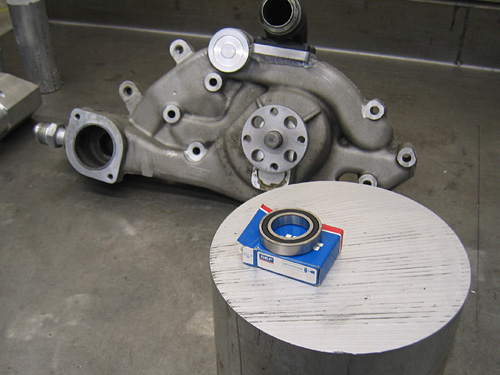

We will then machine our own pulley with a greater width and wall thickness. In our case, as we will use a cogged belt, we must include some flanges (or fences as they are sometimes referred to) to control belt tracking. It has been our experience that the waterpump pulley is best suited for this inclusion. This image also illustrates a bearing which brings up the next weak link in the chain. Once the pulley is upgraded and no longer flexing the next item to assume the load is the waterpump, bearing and shaft. These stock LS-2 pumps have a very compact bearing assembly, probably very adequate for their intended purpose although when we start adding a supercharger into the mix, they become very inadequate. There is promotion to revert back to an earlier, beefier LS-1 style pump (which will bolt up) from the performance aftermarket, although we believe this actually increases concern rather than benefiting. The LS-1 style pump is stronger due to a much larger bearing and shaft arrangement. This requires the nose of the pump to extend forward and necessitates a much deeper cone pulley to bring back the belt footprint. The deeper pulley increases leverage applied to itself and the pump and in our opinion negates all benefit of its selection. Our solution to this problem is to machine a male bearing hub integral to the front of our pulley. We then produce the outboard brace (seen previously) placing the pulley in a double shear anchor. Bullet proof. |

|

|